WhyGelato?

Because There’s More Than One Way to Create a Masterpiece

It’s all about creativity and expression in any form of art, including the art of gelato. And just as a painter chooses the medium that fits their skill and comfort level best, so must the artist in the business of gelato find the best method for their personal taste and business function. So how is gelato made? Let’s examine the possibilities…

The Old Fashion Way

The process of making gelato has evolved over thousands of years. In the beginning, gelato was made with a few simple ingredients. Egg yolks were used as the main stabilizer and were added to the other raw ingredients such as sugar and milk (sometimes water for sorbetto), heated in a large pan/bowl and then chilled. Flavor ingredients (fresh fruit, nuts, chocolate, etc.) were then added and the gelato was batched. Batching gelato is also known as the process in which the gelato is frozen and air is incorporated into it to give it its nice, dense, smooth texture

Batching gelato is also known as the process in which the gelato is frozen and air is incorporated into it to give it its nice, dense, smooth texture.

The tedious Old Fashion Process only allowed gelato makers to be able to make a maximum of 4-5 of the traditional flavors, and the shelf life was not long. While this is the classic “from scratch” recipe , few gelato makers still use this process as technology has redefined the traditional gelato making process without compromising taste and flavor.

Hot Process

At the turn of the 21st century, new technology allowed for the introduction of a new way to make gelato known as the Hot Process. Widely used today, the Hot Process is one of the most highly used processes. The Hot Process involves the use of a pasteurizer, which heats the gelato ingredients up to 85°C for 5 seconds and then drops the temperature to 5°C. This controlling of the process allows for stabilizers and emulsifiers to perform properly, and creates a microbiologically safe mixture.

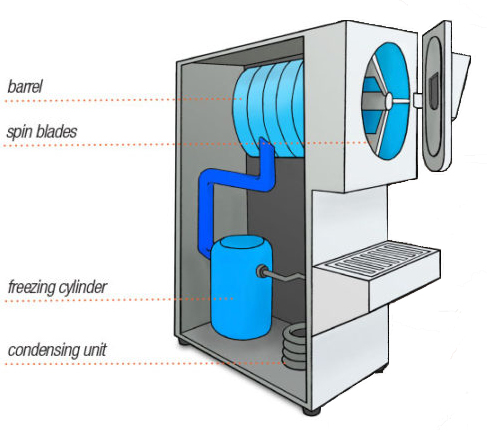

After the pasteurizer, the gelato is placed in a batch freezer. Here, the mix is quickly frozen while being stirred to incorporate air to produce and control formation of small ice crystals that are necessary to give gelato a smooth, creamy texture and a satisfactory overrun (percentage of air). There are some gelato machines that contain both a pasteurizer and a batch freezer, which can simplify the process. Hot process is generally used for gelato because it can allow more flexibility for the customization of recipes, and offers a slightly longer shelf life than all of the other processes.

Cold Process

In the 1980’s, the Cold Process was developed to provide a simpler gelato making process. The Cold Process is the other process typically used by many gelato makers today because it allows for the preparation of gelato to occur in a more efficient manner. The ingredients used in the Cold Process are already microbiologically safe which eliminates the need for a pasteurizer – not only saving gelato shops costs, but also space, as it is one less piece of equipment.

In the Cold Process, the raw ingredients are mixed with a Cold Process base and flavor, and placed directly in the batch freezer, where the gelato is batched and prepared for serving. While the shelf life is slightly less than Hot Process, Cold Process is the answer to gelato makers’ need for a process that achieves a greater amount gelato in a quicker timeframe without compromising taste.

Sprint Process

The gelato market continues to develop, and with this, the needs of the gelato maker have continued to grow and/or change. The Sprint Process is the newest process to make its way into the industry, offering an even easier and quicker way to produce gelato without the intervention of a skilled gelato master. The sprint process is simple; add a liquid ingredient (water or milk) to a prepackaged mixture containing all of the remaining raw ingredients including, flavors, stabilizers and emulsifiers. Then, pour into the batch freezer. The Sprint Process allows little room for error and complete consistency in flavor every time. For gelato shop owners producing large varieties of flavors in a short period of time, the Sprint Process works best. On the downside, the Sprint Process doesn’t leave much room for flavor experimentation and creativity.

The Sprint Process allows little room for error and complete consistency in flavor every time. For gelato shop owners producing large varieties of flavors in a short period of time, the Sprint Process works best.

Regardless of the process used, when the gelato has completed its cycle in the batch freezer, the next step is extraction into the gelato pan. Here’s where the difference in presentation between gelato and American ice cream reveals itself. Gelato is extracted using a spatula, rather than an ice cream scooper. The spatula helps to create creamy waves of gelato that are visually appealing in the display case and truly give gelato its artisanal feel.

Cool Facts

Blast Freezer

In some instances, gelato makers do not immediately serve their gelato, but utilize a blast freezer. The blast freezer contributes to the life of the gelato by freezing it at a lower temperature than a standard freezer. This also helps it maintain its artisanal presentation.

Previous

Next Up…